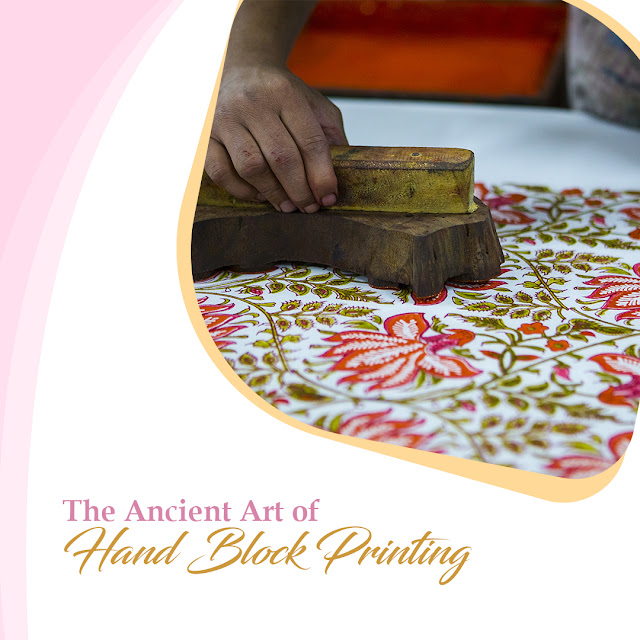

The Ancient Art of Hand Block Printing

The

ancient art of Hand Block Printing has been practiced for

hundreds of years in India. A procedure that requires steady movement and

cautious hand-eye coordination, this fabric printing method involve using carved

wooden blocks dipped in dye to remake suitable designs.

Block-printed

fabrics usually showcase a palette of colors that bring these designs to life.

Block

printing is stated to have originated in China. However, in present-day India,

Bagru in Rajasthan is a key hub of hand block printing. Some Hand

Block Print Fabric Manufacturers use

fruits or vegetable-made ink for printing and make their product fully organic.

Let's have

a different look at the technical Block Printing Process.

Carving

The Design

A master

block maker traces the selected layout onto a woodblock, commonly a teak

product, a deciduous hardwood tree native to India. The woodblock is oiled and

sanded before the craftsman carefully chips away at the block, leaving the

stamp's desired design in the back. In traditional block printing, the layout

itself is most customarily a conventional Indian motif that's generally

prompted by using the region's nature, beliefs, and customs. These motifs

frequently take the form of geometric patterns, animals, or vegetation.

Dying

Base Cotton Fabric

The Main

cloth may be white or a coloration. The mill that produces the organic cotton

material dyes and prepares the base fabric to be block published. Colored

Fabrics are more highly-priced because of the more dyeing steps. They're

usually dyed through a reactive dye manner.

Finding

Perfect Shade

For each

Passion Lilie series and design, we create a shade palette. We use the widely

wide-spread Pantone colorings as a reference. The natural dyes are available in

a few different base shades. These colorings are cautiously blended

collectively to suit the preferred Pantone shade.

Preparing

The Fabric

The cloth

is laid flat on a table and stuck firmly to the desk with pins. Although

miniature versions inside the printing make Indian Block

Print Fabric unique, a single

unwanted motion can result in streaks or choppy printing that imply beginning

another time.

A unique

wood desk is used for block printing. The desk is generally 6 meters in

duration, by 50 inches extensive, and has as a minimum ten layers of jute

material, a blanket layer, and a thick cotton sheet at the pinnacle that is

tightly tucked in from all aspects of the desk. All of these layers assist the

block print in taking and print onto the cloth properly.

Printing

Once the

colors are combined, the grasp block printer pours the dyes onto a rolling dye

tray. The tray has numerous layers of gauze cloth. The form of block- delicate

and light or heavy and full of shade, determines the number of layers of gauze

needed for the dye to spread all over the print part of the block correctly.

The block

print is then dipped in dye and firmly stamped with the aid of a hand onto the

fabric. This calls for a positive amount of force, regularly done either with

the support of hitting the stamp with the assistance of a hand or with the aid

of a hammer. If the design consists of multiple colors, each is applied with

its block after the previous paint has dried—the more hues in a garment, the

more time-consuming and hence expensive the cloth.

Washing

and Curing

Once the

dye has dried, the finished block revealed cloth is sent for washing and

curing. The material is washed by using hand using a sustainable water source

and hung to dry in the solar. Just as the technique of washing reduces water

consumption, this sustainable approach of drying the fabric minimizes strength

consumption for a smaller environmental footprint than many synthetic

procedures. Once the material has dried, it is despatched for curing.

Good hand

block printing calls for talent and plenty of exercises to create uniformity

and clean block printing patterns. Even for grasp block printers, tiny versions

within the manner are part of what offers Indian block print fabric a unique

attraction. Sometimes those versions are the handiest manner to inform the

difference between display screen printed and block published material.

Block-Printed

Clothes are excellent in all types of uses, whether it is in your house or on

your kid's shoulders. You can Try, Shivalaya Jaipur; they offer organic Hand Block Printed

Clothing for almost every use and wear.

Comments

Post a Comment